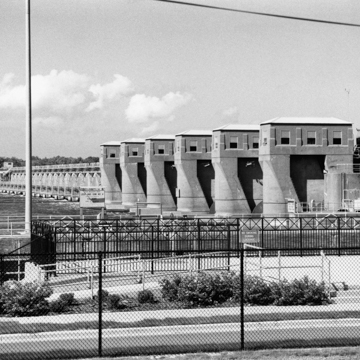

Originally the Upper Mississippi River was capricious—fast and turbulent during floods, too shallow to navigate during dry seasons, rife with snags and shifting sandbars. Today it is a generally smooth and predictable waterway that allows for safe shipping year round. Locks and dams made the difference. Beginning in the 1930s, the U.S. Army Corps of Engineers built twenty-nine dams on the 669-mile stretch of river between Minneapolis and St. Louis. Together, the dams turned the free-flowing upper Mississippi into a stairway-like series of slack-water navigation pools, with locks to lift or lower boats from one pool to the next (see LC8). Each lock-and-dam complex is different, not just because each section of the river is unique but because technology advanced rapidly as the Corps’s work progressed. At Lock and Dam No. 4, the first six dam gates closest to the Wisconsin shoreline are submersible roller gates, sixty feet wide and cylindrical. The No. 4 Dam—the Corps’s first to use submersible rollers—caused less erosion than nonsubmersible roller gates. But by the later stages of construction, in the late 1930s, even these had been superseded by Tainter gates. The twenty-two gates on the Minnesota end of Dam No. 4, each thirty-five feet wide and fifteen feet high, are all Tainter gates. Each has its own motor, like those of the roller gates, but originally a gasoline hoist ran from gate to gate along rails on top of the dam. Although the Corps custom-developed these gates, Jeremiah Tainter of Menomonie patented the basic design in 1886. Knapp, Stout and Company, the giant lumber firm that Jeremiah’s older brother Andrew co-owned, was the first to use them, in his case to release water from the company’s millponds.

Numerous engineers and contractors created Lock and Dam No. 4. William McAlpine, a long-time Corps engineer who also worked on Bonneville Dam and the Tennessee Valley Authority, headed the design team. Engineer W. D. Fairchild oversaw construction. Treadwell Construction Company of Midland, Pennsylvania, designed the roller gates; Ouillmette Construction and Engineering Company of Chicago was general contractor for the lock; and United Construction Company, of nearby Winona, Minnesota, contracted on the dam.

Despite the impressive engineering, not everyone cheered the transformation of the river into a mechanized canal. The Izaak Walton League, concerned that flooding previously dry land would harm the valley’s environment, led a protest during the design phase of Dam No. 4. The Chicago, Burlington, and Quincy Railroad joined in, charging that the dam would damage its right-of-way. In response to these concerns, the Corps lowered the water level of the pool by three feet, but the project still widened the river channel from eight hundred to two thousand feet, inundating much of the flood plain and permanently altering the riparian ecosystem.