The C and H Refinery is a rare industrial site, reputed to be the smallest functioning oil refinery in the world. The refinery was built in 1933 by two former employees of the Ohio Oil Company in eastern Wyoming, whose hours had been severely cut due to the Depression. Roy Chamberlain, chemist and warehouseman for Ohio Oil, formulated a plan to build his own refinery, and recruited fellow employee James Hoblit to join him in the enterprise. Chamberlain secured permission to tap into the existing Ohio Oil pipeline that transported oil from the bountiful Lance Creek Oil Field south to Fort Laramie, passing through the small town of Lusk, which was chosen as the location for the refinery. Lusk’s location was not only convenient to the pipeline, but also to potential consumers in eastern Wyoming and western Nebraska and South Dakota.

Due to changes in oil refining technology (from petroleum distillation to thermal cracking) and the recent consolidation of oil operations in Wyoming by Standard Oil (which also owned Ohio Oil), Chamberlain and Hoblit were able to acquire what was then considered obsolete equipment for their refinery at little to no cost—specifically, stills and other equipment brought to Wyoming in 1895 to build the Pennsylvanian Belgo-American Refinery, the first of many refineries in Casper. Some pieces of equipment in place in the refinery bear the stamp of the Erie City Iron Works in Erie, Pennsylvania, and are thought to be the last remaining pieces of original petroleum processing equipment built by this company.

The refinery occupies about 1.5 acres at the southwestern edge of the town of Lusk, along U.S. Highway 18/20. It consists of several buildings, including the original house/office building, refinery building, and related storage tanks and structures, as well as a gas station/repair shop and a welding shop added in the 1970s. The buildings and equipment, which remain in their original configuration, represent the entire process of petroleum distillation as practiced in the late nineteenth and early twentieth century. It is likely the only operational petroleum distillation refinery in existence, since distillation refining was entirely replaced by the thermal cracking process during the twentieth century.

The house/office building was moved to Lusk from the nearby town of Manville to serve as the refinery manager’s house and business office. A Spanish Colonial, stuccoed, false-front office addition with a stepped parapet with central arch was added to the front of the one-story, gable-roofed frame house (c. 1915) after it was moved to its new location. The symmetrical facade has a central entrance flanked by windows.

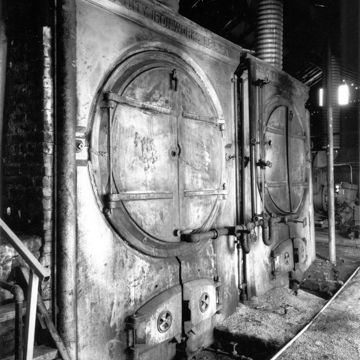

The refinery building is located just to the west of the house/office. It is a single-story, rectangular building sheathed in corrugated metal with a metal roof, no foundation, and a dirt floor. The walls are double corrugated metal panels riveted together and supported by wooden beams, with mud filled in between the exterior and interior panels for insulation. The entire refinery operation, excluding associated cooling towers, heat exchangers, and storage tanks, is contained in this small 28 x 54 x 25–foot-tall building. Almost all the refining equipment inside the building is in its original, fully operational state. Inside the refinery are a boiler and two stills. The doors of the stills bear the markings of the Erie City Iron Works as noted above. Numerous pipelines with many valves and gauges connect the boiler with three steam-driven pumps. Pipes seem to run everywhere in the room.

There are several different types of storage tanks and related equipment also located on the property. Used crude-oil storage tanks were initially brought in for the refinery operation and some stills and tanks were added prior to 1950 in anticipation of expanding the operation. This equipment, still in its original configuration, creates an interesting and likely unique exhibit of early-nineteenth-century crude-oil processing and storage equipment, from pre-1920 hand-riveted stills converted to storage tanks and pre-1930 hand-riveted storage tanks, to bolted and welded tanks from the 1940s. Heat exchangers and a cooling tower complete the operation.

The refinery was successful for several decades, selling home heating oil to local consumers. In 1935 Chamberlain sold his half of the operation to Hoblit, and the refinery was operated by the Hoblit family until Joe Chamberlain purchased it in 1974. The refinery closed in 1978 and was shut down for two decades, during which time the buildings and equipment deteriorated. When Pakistani businessman Zahir Khalid, the current owner, first saw the refinery, he described it as having oil tanks outside a small 28 x 50–foot, sheet-iron building, with holes in the walls and roof. “It was a discouraging sight,” Khalid said, “vines creeping all over the floors and walls, which were giving way with mud oozing out of them.” In spite of his initial skepticism, Khalid was intrigued and bought the property in 1998, restored the equipment, and made the refinery fully operational by 1999, receiving a certificate of operations from the Wyoming Department of Environmental Quality.

References

Khalid, Zahir A., Shahid H Shigri, Robert Breuer, and Mike Cassity, “C & H Refinery District,” Niobrara County, Wyoming. National Register of Historic Places Registration Form, 2000. National Park Service, U.S. Department of the Interior, Washington, D.C.

“The Smallest Oil Refinery in the U.S.” Society for Industrial Archeology Newsletter28, no. 4 (Winter 1999): 13-14.